In the race to electrify the world, the battery remains the most expensive and unpredictable component in the vehicle. For OEMs like Tesla, Rivian, and Ford, and manufacturers like LG and CATL, the challenge isn't just making batteries—it's predicting exactly how they will behave five, seven, or ten years down the road.

Current State of Health (SoH) and Remaining Useful Life (RUL) estimations are often conservative approximations. We believe the industry deserves surgical precision.

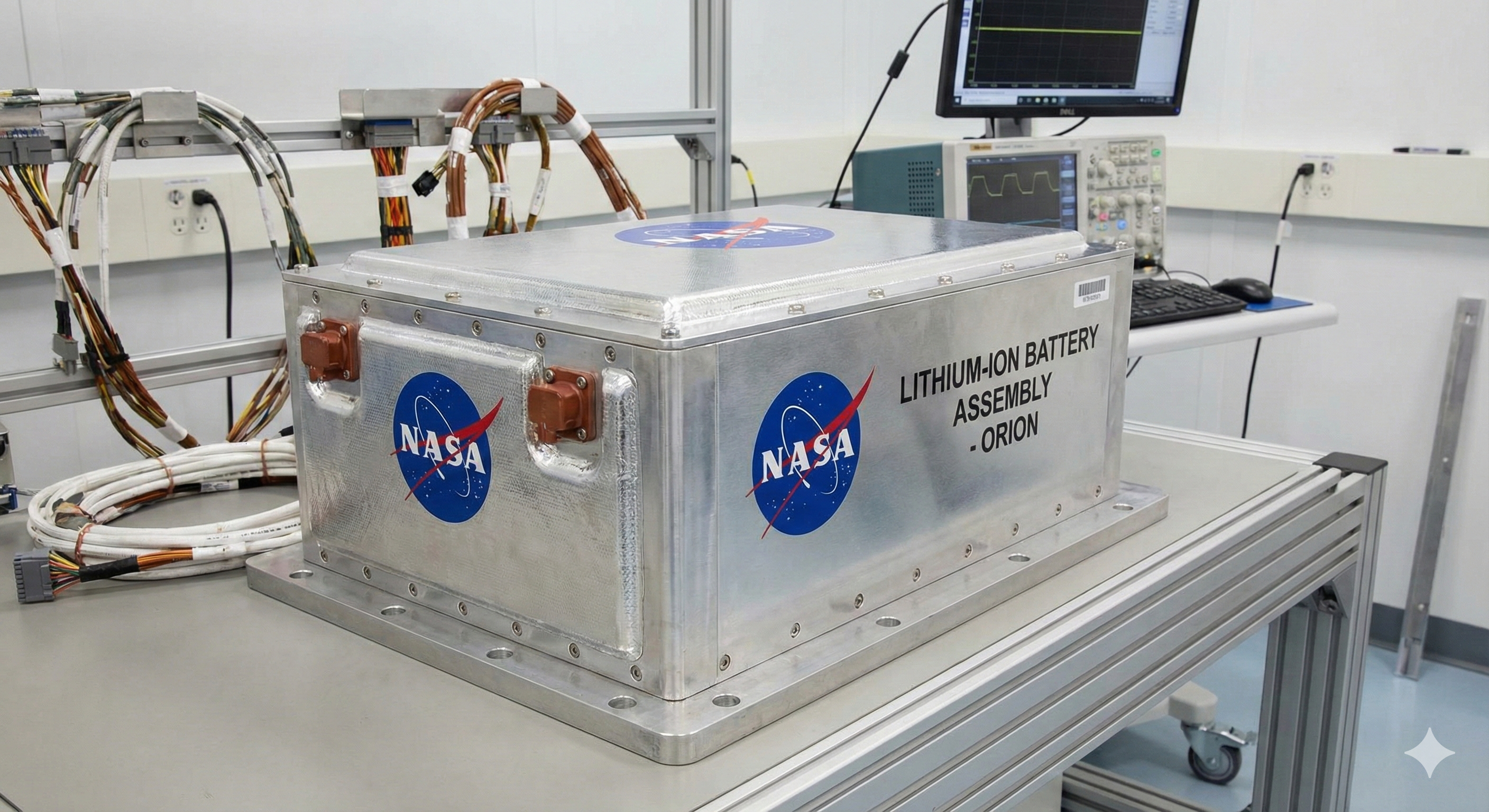

Today, we are sharing results from our latest validation sprint using the industry-standard NASA B0005 Lithium-Ion dataset. The results suggest a new benchmark for predictive accuracy in battery degradation.

The Challenge: The NASA B0005 Benchmark

The NASA B0005 dataset is the gold standard for stress-testing battery algorithms. It involves Lithium-Ion cells run through repeated charge and discharge cycles at varying temperatures until they reach end-of-life (defined as a 30% fade in capacity).

Most models can predict degradation when they have seen 90% of the battery's life. The real challenge is generalizability—can a model predict the death of a battery it has never seen before?

Our Methodology: The "Blind" Test

To prove robustness, we didn't just perform a standard train-test split. We subjected our model to a rigorous 50% Blind Split.

- 50% of the data was used to train the architecture, learning the non-linear physics of degradation.

- 50% of the data was completely withheld. The model had never seen these batteries or their specific degradation curves before making its predictions.

The Results

Running blindly on the hold-out set, our proprietary Deep Learning architecture achieved the following:

Total Accuracy: 92.5%

Average Error (RMSE): 3.67 Cycles

Why "3.67 Cycles" Matters

In the context of RUL (Remaining Useful Life), an error margin of 3.67 cycles is effectively real-time precision. Standard industry models often deviate by 20 to 50 cycles when predicting end-of-life on noisy, real-world data.

By narrowing the error margin to under 4 cycles, we have moved from "estimating" when a battery will fail to "pinpointing" it.

What This Means for the EV Industry

For companies building the next generation of electric fleets, this level of precision translates directly to ROI and safety:

1. Dynamic Warranty Modeling

Instead of blanket warranties that eat into margins, manufacturers can use our predictive scoring to offer dynamic warranties based on specific usage patterns, identifying high-risk packs before they become liabilities.

2. The End of Range Anxiety

A 92.5% accuracy rate in predicting degradation allows for vastly more accurate dashboard range estimations. Drivers can trust the "miles remaining" number implicitly, even as the vehicle ages.

3. Optimized Second-Life Value

When a lease ends, how much is the battery actually worth? With a 3.67-cycle error margin, we can provide an audit-grade "report card" for used EVs, stabilizing the resale market and validating residual values.

4. Safety & Thermal Event Prevention

Sudden knee-points in degradation curves often precede thermal runaway. Our model's high sensitivity to anomalies allows for intervention before a catastrophic failure occurs.

The Road Ahead

Achieving these results on the NASA B0005 dataset is just the beginning. We have proven that our architecture can untangle the complex, non-linear chemistry of Lithium-ion degradation with minimal data.

We are currently opening slots for our Enterprise Pilot Program. If you have fleet data sitting in the cloud, we can turn that noise into precise, actionable intelligence.

Want to Learn More?

If you're interested in applying this technology to your battery data:

- Check out our Marketplace for available prediction algorithms

- Contact us at support@superset.ai

- Sign up to get started with Superset